Vegetable Oil

From the field into the tank

Various types of vegetable oil can be directly used after extraction as fuel in adapted diesel engines. Considerable for the European region are rapeseed and sunflower oil. After harvesting, the raw materials are transported to vegetable oil presses, where the seeds are first crushed and pressed afterwards. The press residues (so-called oilcake) can be used as animal feed in agriculture or as basis for energy production through combustion. After pressing, the vegetable oil is filtrated to separate dissolved suspended matter. Since 2010 the norm DIN51605 is applicable for rapeseed oil as fuel.

The pressing can be done locally in decentralised plants through decating, in those the processing capacity is relatively low. The procedure is comparatively simple and lowin energy consumption; the vegetable oil is gained solely by mechanical pressure (in extruding presses). The residue (“oilcake”) contains 10% residual oil and can be used as animal feed in agriculture.

In centralised large-scale plants processing capacity and energy requirement are significantly higher.

Furthermore the manufacturing process is different through a higher press temperature and a follow-up treatment of the oilcake, where the residual oil is recovered through solvent extraction. The used solvents need to be removed from the press residue, before the so-called extraction meal can be used as animal feed like the oilcake.

Whereas for biodiesel production transesterification is necessary, vegetable oil can be used immediately after pressing and follow-up treatment as fuel in adapted diesel engines. The quality of the particular vegetable oil is depending on the concentration of different fatty acids.

How long the prepared vegetable oil can be used as fuel depends on the storage conditions. As a rule of thumb it can be used 6 months to 1 year. Keeping the temperature in the storage tank at a constant level, avoids condensation. Also direct light irradiation and the diffusion of water can deteriorate the quality of the vegetable oil.

Due to the different fuel quality of vegetable oil and diesel, adaptions to the diesel generator have to be made, before the engine can be driven by vegetable oil. Because the oil needs to be warmed up at a cold start, the so-called double-tank system is applied. Here the engine is operating with diesel as long as the operating temperature is reached. Afterwards the system switches over to vegetable oil as fuel either manually or automatically.

The environmental effects of vegetable oil

While biodiesel is esterified, oil can be used immediately as fuel after pressing from oilseed (e.g. rapeseed or sunflower seeds) and follow-up treatment. In the ecobalance of vegetable oil methanol can be disregarded, usually it comes from fossil sources. As a consequence the result of the energy balance of vegetable oil compared to biodiesel is affected positively. One litre of vegetable oil can, depending on the oil seed, substitute 0.96 litre of fossil diesel fuel.

Vegetable oil is a very environmentally friendly fuel, which is non-toxic and therefore doesn’t pose a threat to stretch of water, soil, ground water or drinking water.

Vegetable oil – Made in Austria

In 2009 17,784 tons of vegetable oil were consumed in Austria, 2,656 tons from that were covered through local production. Vegetable oil is often used in farms and for agricultural vehicles.

In 2008 the consumption was 19,276 tons; in 2007 18,000 tons. Due to increased costs of seeds and seedlings and because of the additional price decrease of fossil energy sources the production volume of vegetable oil is currently declining (according to the Federation of Vegetable Oil Austria). In 2007 the quantity of vegetable oil produced in Austria was still 3,578 tons, in 2008 there was a decline of the output to 3,389 tons, before the local production dropped to 2,656 tons in 2009.

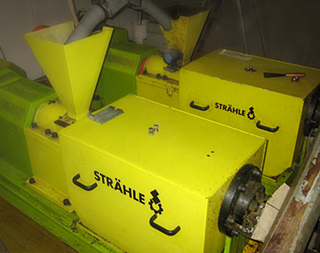

Vegetable-oil press

(c) Agrarplus